“OUR VISION IS TO DELIVER QUALITY MASS TIMBER

BUILDING SYSTEMS TO MASS MARKETS” – Gaetan Royer | CEO

VISION

MISSION

Massive Canada offers mass timber solutions for our sustainable future. Our mission is to make mass timber mainstream. High-quality products that stand the test of time.

VISION

We are the first manufacturer to combine the remarkable strength of mass timber with the speed and efficiency of prefabrication. We innovate. We focus on high quality, durable, well-constructed, comfortable spaces to live, work and play.

We leverage automation and assembly lines to build more quickly in our manufacturing plants and on your building site.

We use wood – a natural, renewable resource which consumes 20 times less energy than steel. Wood locks in carbon for the life of our buildings. We use state-of-the-art technology building systems. We secure international certifications for our building components.

Natural and local materials plus innovation leads us to a sustainable economy. We developed a better way to build, efficiently and more affordably. Designed using artificial intelligence and circular economy principles, our buildings have a much smaller environmental footprint.

Most importantly, human response to a biophilic material like wood contributes to the well-being of people who occupy our buildings.

OUR VALUES

At Massive, we use a circular economy lens to make decisions. We are committed to using clean energy and eliminating waste. We design our products to be durable and kept in circulation for generations.

We respect the forests we rely on. We recognize the stewardship of First Nations who cared for forest habitat for centuries. We are transparent in our use of natural resources. We do what we say we are going to do.

Projects around the globe, particularly in Europe, show that construction can indeed move to assembly lines. New buildings can be pre-assembled in a controlled environment, away from the mud and rain we of construction sites. Massive prefabricates apartment-size modules using engineered wood from sustainably harvested new growth forests. AI design helps us use far fewer greenhouse gases and reduce waste.

It’s time to rethink, retool and rebuild the construction industry. It’s time to get recycling from under the kitchen sink and foster a circular economy on a grand scale, the size of an eighteen-storey tower.

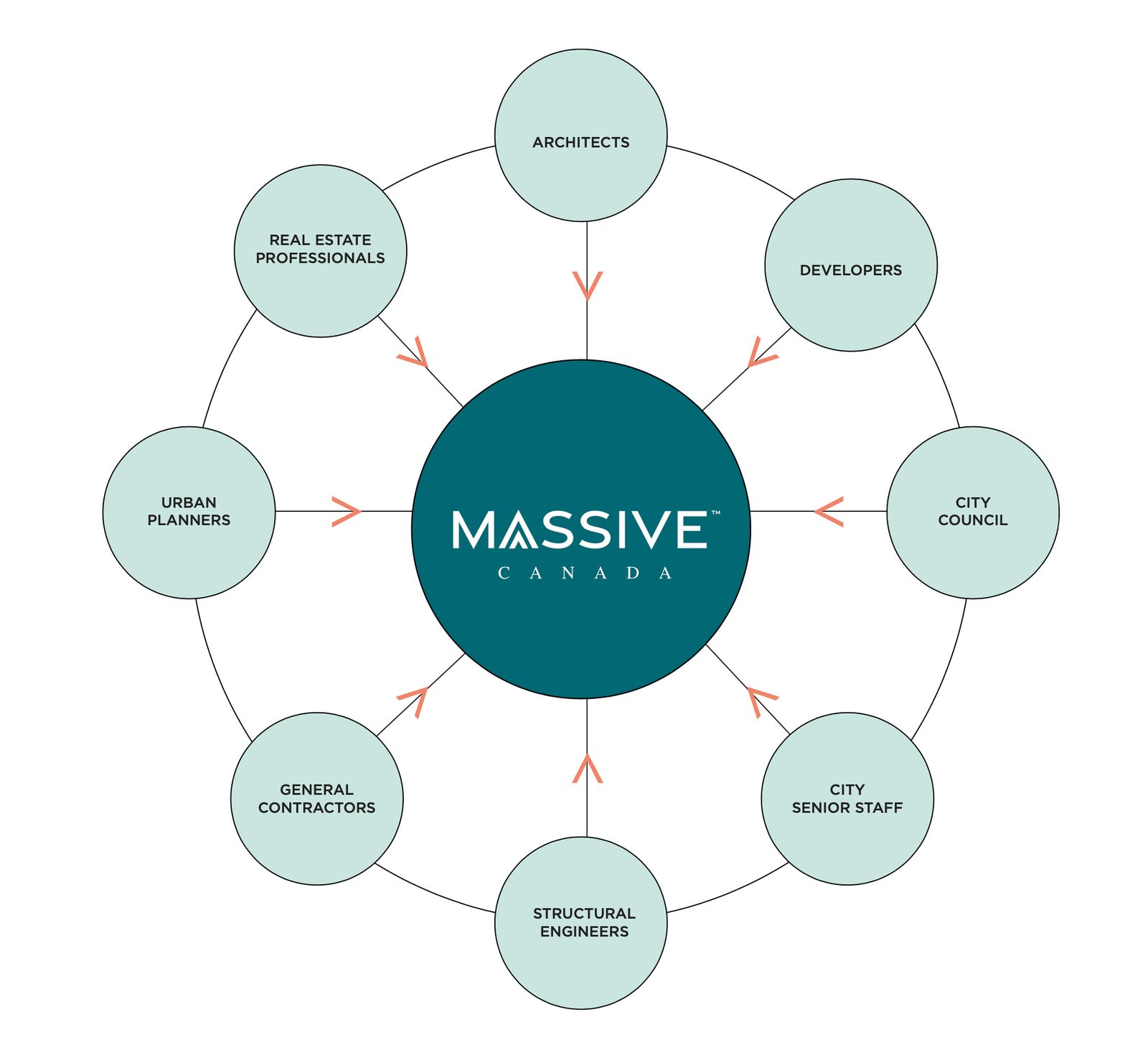

A complete rethinking of how we build requires the full integration of architectural, structural, mechanical, electrical, energy performance and code compliance disciplines. It also requires close working relationships with all owners, design professionals, approval authorities, general contractors and builders.

POSITIVE IMPACT

Leaders who assess their project through a rigorous process of value engineering realize that mass timber, AI design, off-site manufacturing and Massive Canada’s INTEGRATED BUILDING SYSTEM achieves their goals while saving them time and money.

MARKET IMPACT

The growth of prefabricated, engineered wood products around the world is continuing to accelerate. More architects and developers use prefabricated mass timber instead of concrete and steel, simply based on proven success and environmental benefits.

In Sweden, 80% of the new dwellings built in 2022 were prefabricated.

B.C. is well known as a North American leader in mass timber innovation, production and use. BC has more mass timber buildings per capita than any other place in North America. BC leads the country with over 285 mass timber buildings (as calculated by the BC Govt office of Mass Timber Implementation at the end of 2022).

This growing trend is the result of innovations in mass timber systems, enabled by regulatory changes that allow taller structures. The result is that many prefabricated and modular products that use wood composite can provide reliable, affordable, high-performance buildings on an accelerated schedule.

Market demand is aligned with the BC government’s objectives.

1. Better energy efficiency,

2. Lower greenhouse gas emissions,

3. Higher value-added forest products,

4. Good paying jobs for workers in a clean and green economy,

5. More economic opportunities in every part of BC.

These factors drive demand for mass timber manufacturers like Massive Canada to address water and fire damage, energy efficiencies, durability and the high cost of insurance. The growing market demand for engineered wood, as note by the Canadian Wood Council, creates a great climate for investment in the wood industry.

Mass timber uses state-of-the-art technology to glue, nail, dowel and press ordinary lumber together in tight layers. This results in large structural panels, posts, and beams that are lighter than steel and as strong as steel and concrete.

Massive Canada is the first manufacturer to combine the strength of mass timber with the speed and efficiency of prefabrication to create apartment-size modules.

Massive Canada developed strategic relationships and business alliances with elite suppliers and professionals. Massive Canada is actively working with developers to build projects that are at various stages of design and implementation. Massive Canada is poised to become a prolific builder and an iconic mass timber brand.

Massive Canada’s business plan was scrutinized by BC officials. In June 2023, BC Premier David Eby came to Williams Lake to launch the Manufacturing Jobs Fund and announce a $10 million commitment in support of our manufacturing facility and the high value permanent jobs it will create.

MASSIVE CANADA GRATEFULLY ACKNOWLEDGES BC’S FINANCIAL SUPPORT